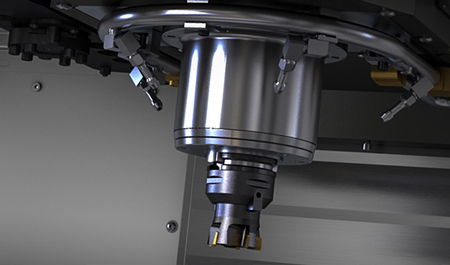

加工中心程序運行故障分析

時間:2021-09-29 11:55:05?? 作者:未知 點擊:0次

加工中心程序運行故障分析:程序運行結束后,出現刀具返回原點時越位,這種現象一般是由機械傳動系統運行阻力太大引起的。切削進給時,刀架低速運行,低電壓驅動,步進電機運轉轉矩小,不足以克服阻力造成丟步。 而回零時步進電機高壓驅動,運行速度高,力矩大,又沒有吃力阻力,步進電機運轉正常不丟步。

而回零時步進電機高壓驅動,運行速度高,力矩大,又沒有吃力阻力,步進電機運轉正常不丟步。

這(zhe)(zhe)樣去時(shi)(shi)丟(diu)步(bu)(bu)而返(fan)回(hui)時(shi)(shi)正(zheng)(zheng)常就會造成(cheng)上(shang)述現象。加(jia)(jia)工(gong)(gong)中(zhong)心程(cheng)序這(zhe)(zhe)時(shi)(shi)可檢(jian)查步(bu)(bu)進電(dian)機(ji)(ji)減(jian)速箱(xiang)內傳動(dong)齒輪或(huo�������)(huo)步(bu)(bu)進電(dian)機(ji)(ji)與絲杠之間傳動(dong)齒輪上(shang)有無鐵屑異物,或(huo)(huo)溜板鑲條是否太緊使(shi)運行(xing)阻力增(zeng)(ze�����ng)大(da)等原因(yin)。這(zhe)(zhe)一(yi)現象一(yi)般是控制系統故(gu)障(zhang)引起的。刀(dao)具在進給(gei)或(huo)(huo)在加(jia)(jia)工(gong)(gong)時(shi)(shi)要求(qiu)低速運行(xing),加(jia)(jia)工(gong)(gong)中(zhong)心程(cheng)序這(zhe)(zhe)時(shi)(shi)步(bu)(bu)進電(dian)機(ji)(ji)運轉速度較低,采用低壓(ya)電(dian)源供電(dian),而程(cheng)序回(hui)零(ling)點(dian)時(shi)(shi),要求(qiu)快(kuai)速退回(hui),這(zhe)(zhe)時(shi)(shi)要求(qiu)步(bu)(bu)進電(dian)機(ji)(ji)高速運行(xing),采用高壓(ya)驅動(dong)電(dian)源,使(shi)輸(shu)出轉矩增(zeng)(zeng)大(da),保證正(zheng)(zheng)常回(hui)零(ling)。控制高壓(ya)驅動(dong)電(dian)源輸(shu)出的有一(yi)開(kai)關(guan)(guan)三極(ji)管,當開(kai)關(guan)(guan)三極(ji)管損壞后,高速回(hui)零(ling)點(dian)時(shi)(shi),高壓(ya)電(dian)源打不(bu)開(kai),步(bu)(bu)進電(dian)機(ji)(ji)輸(shu)出轉矩不(bu)夠,造成(cheng)回(hui)零(ling)丟(diu)步(bu)(bu),致使(shi)刀(dao)具返(fan)回(hui)不(bu)到原點(dian)。加(jia)(jia)工(gong)(gong)中(zhong)心程(cheng)序這(zhe)(zhe)一(yi)故(gu)障(zhang)更換開(kai)關(guan)(guan)三極(ji)管即可消除。